Drainage

& Utility

Plows

Plow With Power

The Double-Link Plow is the most agile option for reacting to grade changes and uneven terrain.

The optimal choice in holding grade for tough conditions.

The Single Arm will hold grade in difficult terrain similar to the Parallel Link and floats in a comparable motion as a Double Link. It is the versatile option for tough conditions and speed.

Plow With Power

The Double-Link Plow is the most agile option for reacting to grade changes and uneven terrain. The Parallel-Link Plow is the optimal choice in holding grade for tough conditions. The Single Arm will hold grade in difficult terrain similar to the Parallel Link and floats in a comparable motion as a Double Link. It is the versatile option for tough conditions and speed.

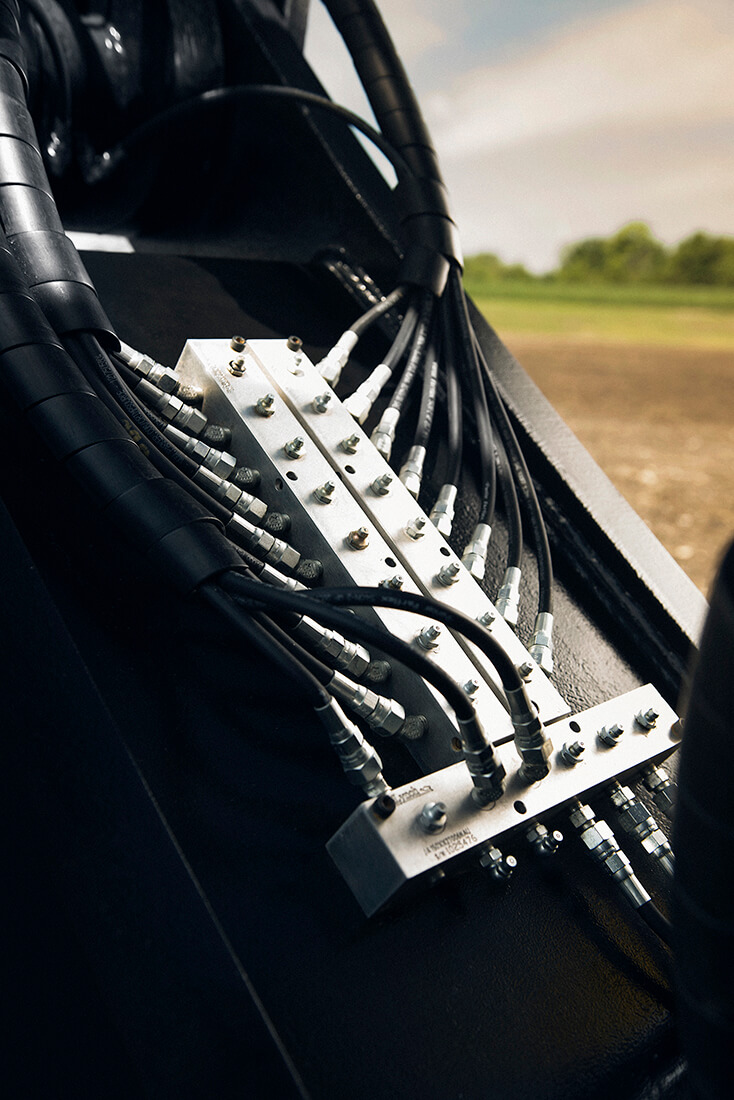

Central Lube Station

Allows safer and easier greasing from central locations. The optional auto-lube feature reduces manual maintenance while ensuring that all lubrication points are getting the proper amount of grease.

Under Hood Accessibility

The hoods are designed with extra clearance when open for easy maintenance access to the engine and hydraulics.

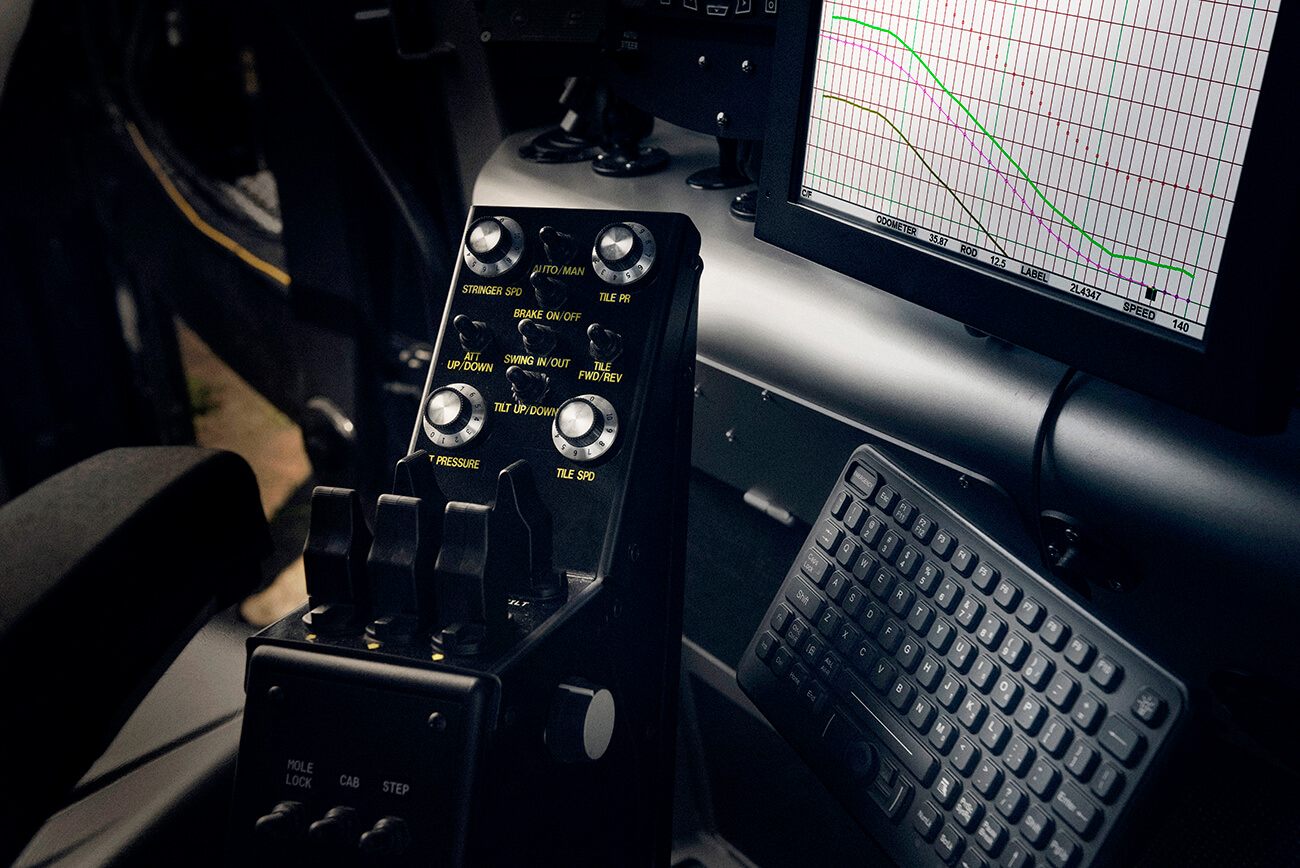

Touch Screen Controls

Wolfe control systems are designed to maximize productivity. The main machine controls are integrated with the seat to move with the operator. The seat can be configured with single or dual joystick controls. The Danfoss Plus+1® monitoring system has both touch screen interface and button controls.

The user-friendly interface allows the operator to monitor and maneuver the machine with ease. All screens and peripherals are mounted on adjustable stalks. GPS systems are available with large touch screens and keyboard controls (supplied by others).

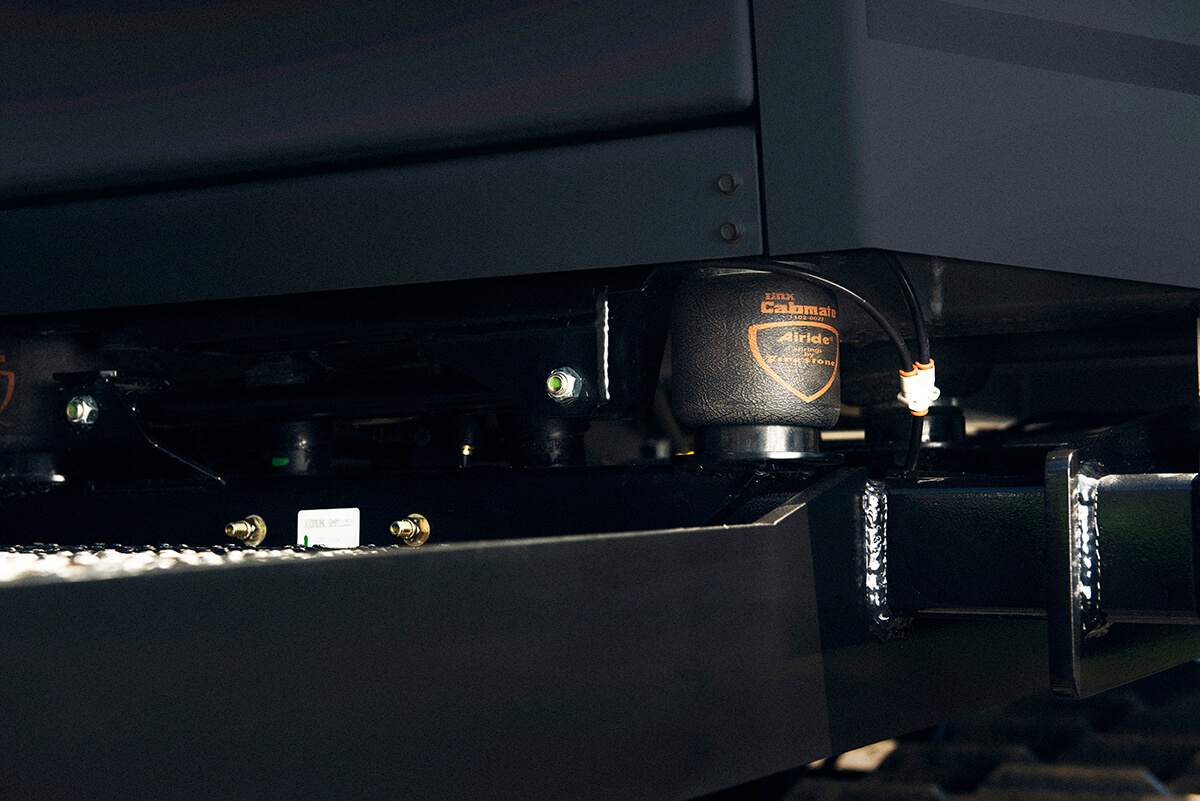

Cab Comfort

The air-ride cab and air-ride swivel seat create a comfortable, low vibration work environment. Large windows in the side-mounted cab provide an unobstructed view of the work zone. The 4 speaker sound system, connected to a Bluetooth radio, provides operator entertainment. The digital climate control system maintains maximum comfort in all weather conditions. An available camera package increases the field of view around the machine, customizable to user preference.

Seat/Machine Controls

Wolfe control systems are designed to

maximize productivity. The main machine controls are integrated with the seat to move with the operator. The seat can be configured with single or dual joystick controls. The Danfoss Plus+1® monitoring system has both touch screen interface and button controls.

The user-friendly interface allows the operator to monitor and maneuver the machine with ease. All screens and peripherals are mounted on adjustable stalks. GPS systems are available with large touch screens and keyboard controls (supplied by others).

Air Ride Cab

The air ride cab & swivel-seat creates a comfortable, low vibration work environment. Large windows in the side-mounted cab provide an unobstructed view of the work zone. The 4 speaker sound system, connected to a Bluetooth radio provides operator entertainment. The digital climate control system maintains maximum comfort in all weather conditions. An available camera package increases the field of view around the machine, customizable to user preference.

Reel Carrier Closed

The compact design has the ability to be folded up for easy transportation and quick field-ready transitions. Customized reel carriers available upon request.

Reel Carrier

The compact design has the ability to be folded up for easy transportation and quick field-ready transitions. Customized reel carriers available upon request.

Tile Feeder

The 4"-6"- 8" [100mm-150mm- 200mm] tile feeder utilizes variable speed, pressure regulated hydraulics and comes with either a rubber or cleated steel drive wheel.

GPS Arm

The GPS arm is equipped with an electric actuator that allows it to fold down during shipping.

Oscillating Tracks & 7 Degree Side Tilt

Both tracks move independently to ensure optimal balance and traction while providing a smoother ride for the operator. The side tilt feature automatically or manually keeps the mole vertical ensuring a precise grade on sloped terrain.

718 Bonfiglioli Heavy Duty Final Drive 180,000NM

The 718 Bonfiglioli Heavy Duty Final Drive 180,000NM is the largest final drive in the industry. These drives have the ability to turn our 58 or 65 link tracks. Tracks are available in an extreme duty configuration with welded grouser bar for added traction.

Features

-

Optimal Machine Cooling

The machine cooling system is designed with variable speed reversing fans. The variable speed fans help reduce fuel consumption while the auto/manual reversing feature makes for easy cleaning when operating in dusty conditions.

-

Fuel Efficient Technology

Industry leading control systems reduce fuel consumption in the following ways;

- Load sensing pumps provide full power when needed. Pumps will dial back under low load situations to reduce wasted energy in the hydraulic system.

- Variable speed fans are controlled to run the at optimal cooling speed.

- Auto idle reduces engine RPM automatically when controls are in neutral for more than 3 seconds. Any operator input immediately returns engine RPM.Wolfe continually strives to utilize the newest fuel saving technology to reduce operating costs.

-

Under Hood Accessibility

The hoods are designed with extra clearance when open for easy maintenance access to the engine and hydraulics.

-

Tile Feeder

The 4"-6"-8" [100mm-150mm-200mm] tile feeder utilizes variable speed, pressure regulated hydraulics and comes with either a rubber or cleated steel drive wheel.

-

Rear-Step & Platform

The rear-step is designed to allow operators to easily get on and off the machine quickly and safely while reducing fatigue. The optional hydraulic lift allows the stairs to be raised for extra ground clearance.

-

Oscillating Tracks (Option)

Both tracks move independently to ensure optimal balance and traction while providing a smoother ride for the operator.

-

7 Degree Side Tilt (Option)

The side tilt feature automatically or manually keeps the mole vertical ensuring a precise grade on sloped terrain.

-

Reel Carrier (Option)

The compact design has the ability to be folded up for easy transportation and quick field-ready transitions. Customized reel carriers available upon request.

-

Central Lube Station (Option)

Allows safer and easier greasing from central locations. The optional auto-lube feature reduces manual maintenance while ensuring that all lubrication points are getting the proper amount of grease.

Standard Equipment

- 540HP CAT™ C-15 ENGINE

- Three-Speed Drive System

- 1st Max: 120 ft/min [2.2km/h]

- 2nd Max: 240 ft/min [4.4km/h]

- 3rd Max: 370 ft/min [6.8km/h]

- Proportional Hydraulics

- 58 or 65 Link Tracks available with standard or extreme pads

- GPS and Laser compatible

- Dual or Single Stick Track Control System

- 718 Bonfiglioli™ heavy duty final drive 180,000NM

- State-of-the-art Plus 1® Electronic Over Hydraulic Control System with complete machine monitoring, diagnostics, and feedback to protect your machine for the long term

- A/C and Heated cabs C/W digital climate control

- Side mounted cabs to increase the visibility of the work zone and sight line while driving

- Engine cooling system with auto/manual reversing fans for cleaning during operation in dusty conditions

- Highest ground clearance in the industry

- Built-in air compressor

- Standard or long mole length available with 8" and 10" points [20cm and 25cm]

- Replaceable QT 400 points, groover, top and bottom plates

- Hydraulic driven, pressure regulated tile feeder

- GPS arm

- Machine Weight Range: 68,500lbs - 86,400lbs [31,000kg - 39,200kg]

- Auto Idle

- Engine Block Heater

Optional Equipment Add-Ons

- Compact Reel Carrier

- Oscillating Tracks

- 7 Degree Tilt Frame C/W auto sensing

- Auto/Manual Lube Manifold

- Custom Colours Available

- Extended Grouser Bars

- Hydraulic Oil Pre-Heater

- Tile Cutter and Crusher System

- Optional Shoe Widths

- 600HP Cat™ C-18 Engine

- Raise and Lower Shoe

- Cable Tow System

- Cameras and View Monitors

- Lights

- GPS and Laser Systems

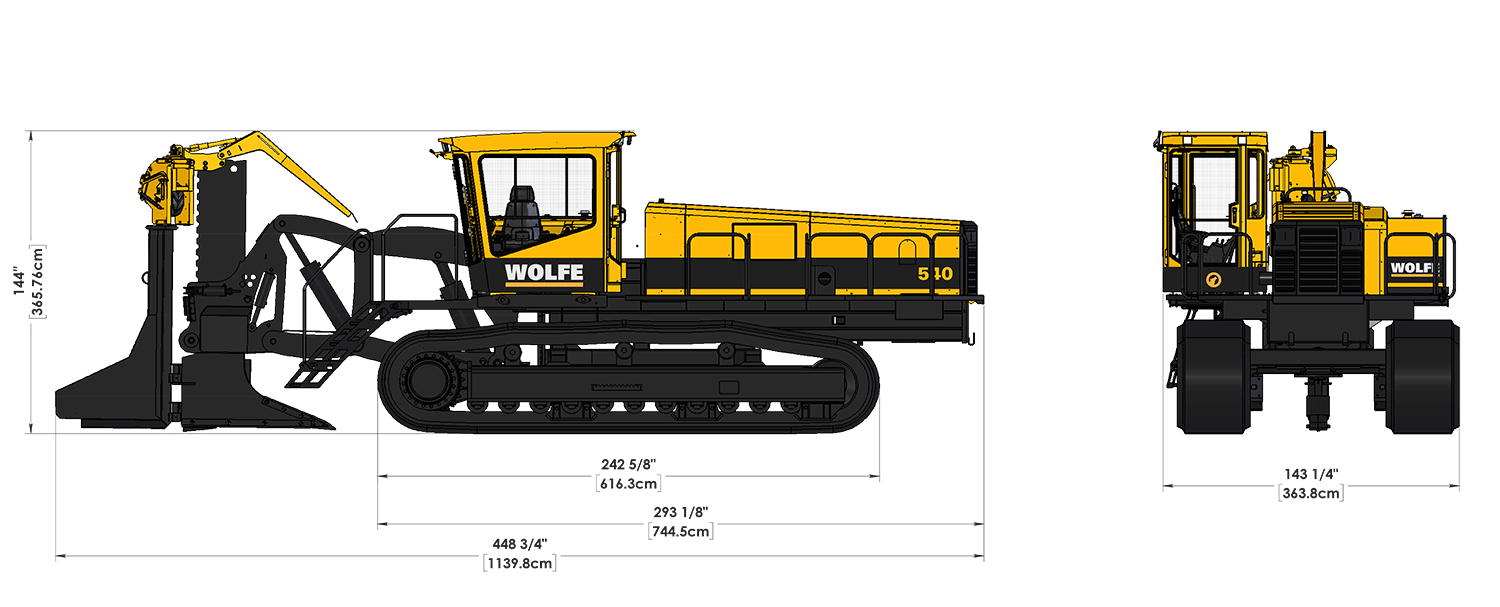

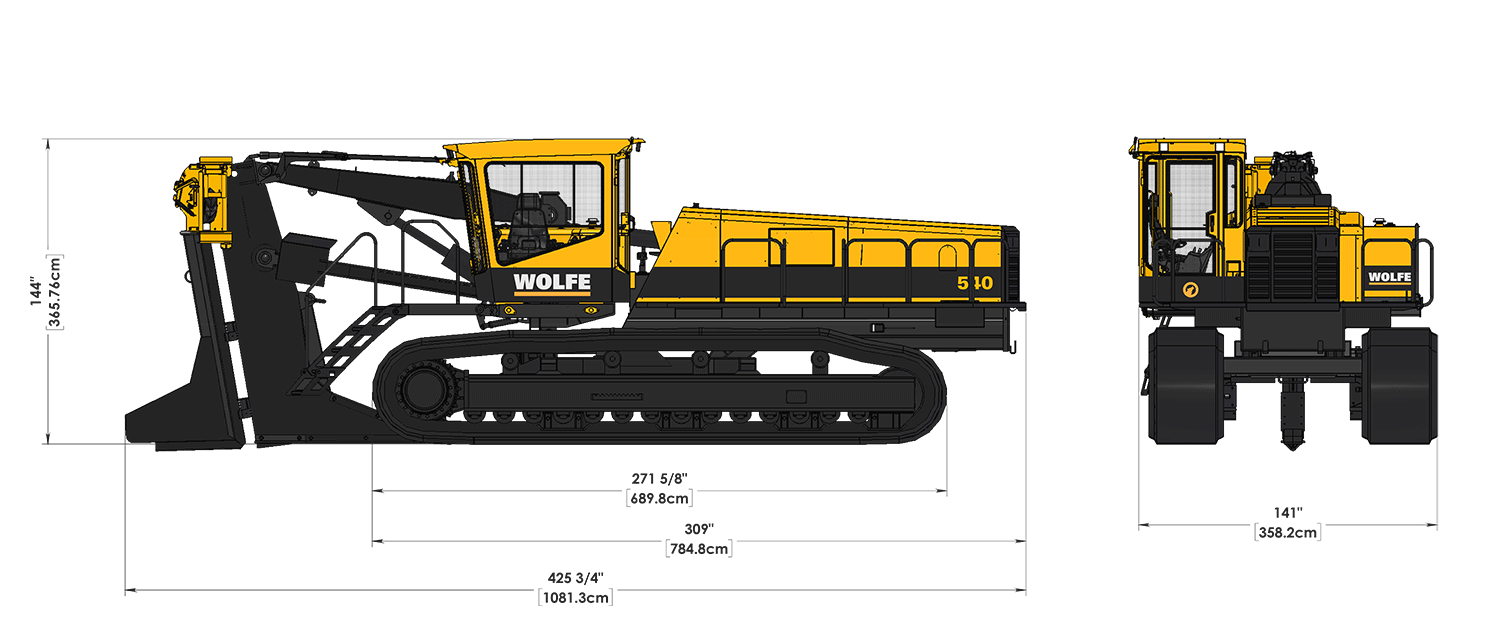

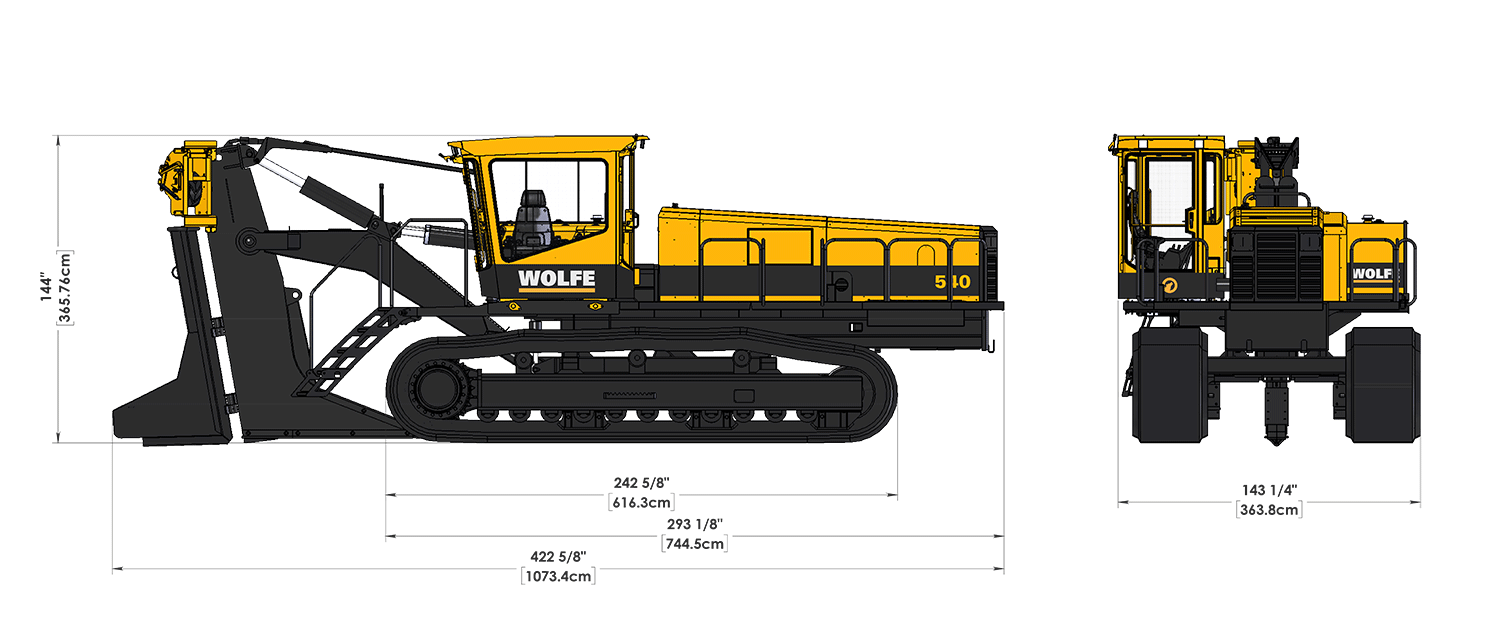

Technical Drawing

All machines are licensed by the Ontario Minsitry of Agriculture, Food & Rural Affairs (OMAFRA).