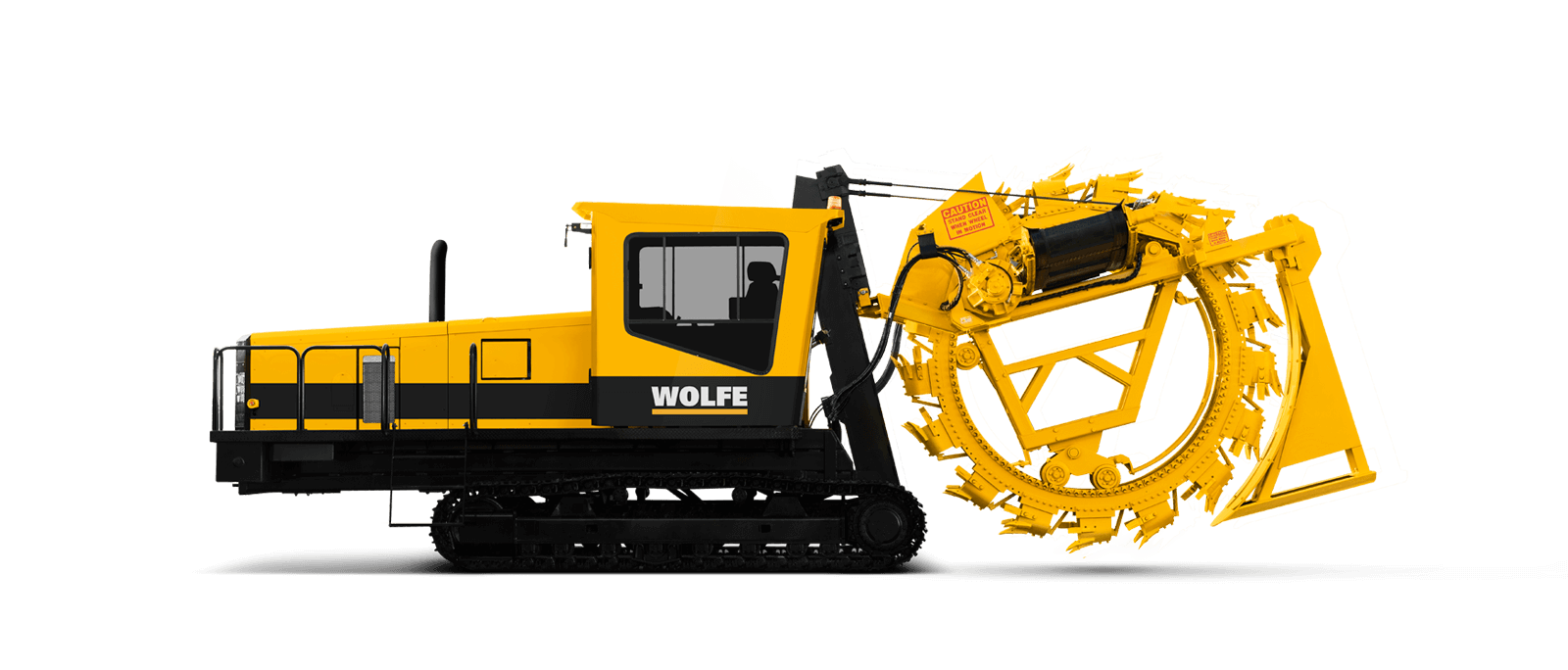

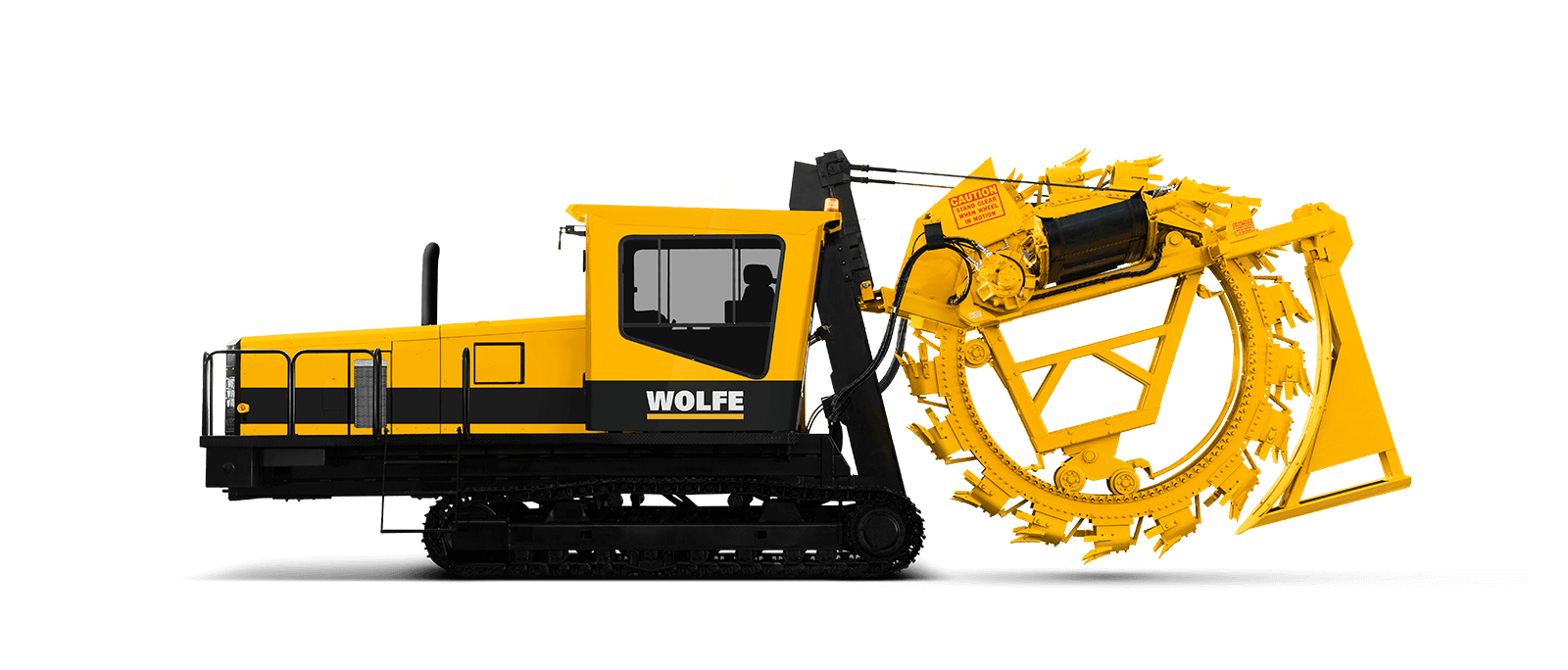

Wheel

Trenchers

Trench with Power

The Wolfe 7000 features a wheel with a maximum trench depth of 7ft. [210cm] and up to 36" [91cm] trench width.

The Wolfe 8000 features a wheel with a maximum trench depth of 8 ft. [244cm] and up to 46" [117cm] trench width.

Trench With Power

The Wolfe 7000 features a wheel with a maximum trench depth of 7ft. [210cm] and up to 36" [91cm] trench width. The Wolfe 8000 features a wheel with a maximum trench depth of 8 ft. [244cm] and up to 46" [117cm] trench width.

Upper Carrier Roller

The double bottom roller, upper carrier roller, drive shaft roller & rear carrier roller are a superior design in wheel trencher technology. The load is evenly distributed across multiple points. Therefore increasing bearing longevity & reducing wear on contact points.

Seat/Machine Controls

Controls are ergonomically placed on both sides of the rotating seat & move with it as it swivels. By always having the controls within reach, operators can comfortably navigate while always overseeing all areas of the job.

Cab Comfort

Increased operator comfort and reduce fatigue. The air set lessen vibration and bouncing, increasing operator comfort.

Bucket Cleaners

The bucket cleaners are responsible for clearing out built up material. This allows the material to fall onto the conveyor & be distributed to the side of the trencher.

Drive Shaft Roller

The double bottom roller, upper carrier roller, drive shaft roller & rear carrier roller are a superior design in wheel trencher technology. The load is evenly distributed across multiple points. Therefore increasing bearing longevity & reducing wear on contact points.

Conveyor

The conveyor is used for distributing material to the side of the machine. With the forward/reversing conveyor belt, the material can be deposited on either side of the trencher.

Roller Technology

The double bottom roller, upper carrier roller, drive shaft roller & rear carrier roller are a superior design in wheel trencher technology. The load is evenly distributed across multiple points. Therefore increasing bearing longevity & reducing wear on contact points.

Rear Carrier Roller

The double bottom roller, upper carrier roller, drive shaft roller & rear carrier roller are a superior design in wheel trencher technology. The load is evenly distributed across multiple points. Therefore increasing bearing longevity & reducing wear on contact points.

Cutting Teeth

Multiple cutting teeth can be fixed to the buckets. Excavating teeth are standard for cutting under normal ground conditions. Carbide teeth are an option used for cutting in difficult or hard ground conditions.

Under Hood Accessibility

The hoods are designed with extra clearance when open for easy maintenance access to the engine and hydraulics.

7 Degree Side Tilt

The side tilt feature automatically or manually keeps the mole vertical ensuring a precise grade on sloped terrain.

The XD upgrade package includes:

- 1.5" [3.8cm] Thick Wheel Rims and Buckets.

- Wider Drive Sprockets and Wheel Segments.

- Extreme Duty Lower Rollers & Upper Trucks.

- 30" [76.2cm] - 36" [91.5cm] Trench Width.

- Heavy Duty Uprights and Sliders, Mast Cylinder, and Pivot Assemblies.

- With the Special tooth holders, it can be equipped with flat digging or carbide bullet teeth.

Features

-

Optimal Machine Cooling

The machine cooling system is designed with variable speed reversing fans. The variable speed fans help reduce fuel consumption while the auto/manual reversing feature makes for easy cleaning when operating in dusty conditions.

-

Fuel Efficient Technology

Industry leading control systems reduce fuel consumption in the following ways;

- Load sensing pumps provide full power when needed. Pumps will dial back under low load situations to reduce wasted energy in the hydraulic system.

- Variable speed fans are controlled to run the at optimal cooling speed.

- Auto idle reduces engine RPM automatically when controls are in neutral for more than 3 seconds. Any operator input immediately returns engine RPM.Wolfe continually strives to utilize the newest fuel saving technology to reduce operating costs.

-

Under Hood Accessibility

The hoods are designed with extra clearance when open for easy maintenance access to the engine and hydraulics.

-

Boom Lift (Option)

The boom life provides a convenient method of installing pipe sections into the trench.

-

Trench Box (Option)

The trench box provides a protected working area behind the trenching wheel for installing pipe sections. This also allows for continuous lengths of pipe or cable products to be installed. Custom configurations available upon request.

-

7 Degree Side Tilt (Option)

The side tilt feature automatically or manually keeps the wheel vertical ensuring a precise grade on sloped terrain.

-

Carbide Cutting Teeth (Option)

Carbide cutting teeth are capable of cutting through frost & more abrasive soil conditions than standard teeth. Various sized wheel trenchers can be equipped with carbide teeth.

-

Side Cutters (Option)

Side cutters increase the trench width by 6" [15.2cm] without changing the bucket system.

Standard Equipment

- 440HP CAT™ C-15 ENGINE

- Two-Speed Drive System

- 1st Max. 120 ft/min [2.2km/h]

- 2nd Max. 260 ft/min [4.75km/h]

- Proportional Hydraulics / load sensing pumps

- CAT™ 320 style 49 link tracks c/w 20" [70cm] street pads

- Dual or Single Stick Track Control System

- State-of-the-art Plus 1® Electronic Over Hydraulic Control System with complete machine monitoring, diagnostics, and feedback to protect your machine for the long term

- Side Mounted Cabs (Left or Right hand)

- A/C and Heated Cabs C/W digital climate control

- GPS and Laser compatible

- Engine Cooling System with auto/manual reversing fans

- Built-in Air Compressor

- Engine Block Heater

- Auto Idle

- Heavy Duty Components

- 1.25" [3.17cm] thick wheel rims

- Heavy duty bolt-on wheel segments

- Heavy duty heat treated buckets

- Heavy duty drop forged teeth

- Dual lower truck roller

- Rear upper truck roller

- Upper carrier truck roller (Head shaft support)

- Machine Weight Range: 52,500lbs - 70,000lbs [23,814kg - 32,000kg]

Optional Equipment Add-Ons

- 7 Degree TILT FRAME C/W AUTO SENSING

- BOOM LIFT

- EXTREME DUTY (XD) PACKAGE

- TRENCH BOX

- AUTO/MANUAL LUBE MANIFOLD

- CUSTOM COLOURS AVAILABLE

- Wolfe heavy duty 57 link tracks c/w 31.5" [80cm] single grouser pads

- Carbide Cutting Teeth

- Side Cutters

- Hydraulic Oil Pre-Heater

- Cable Tow System

- Cameras and View Monitors

- Exterior Light Package

- Auto Steer Ready

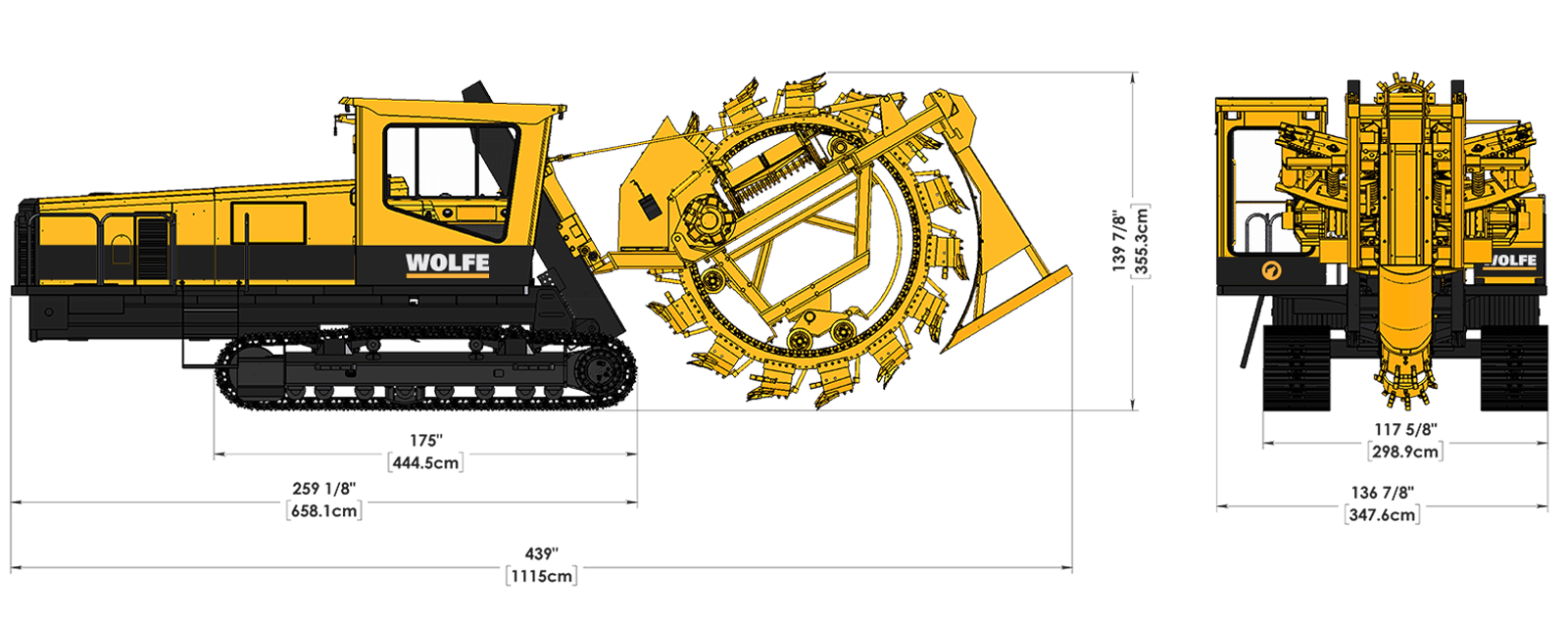

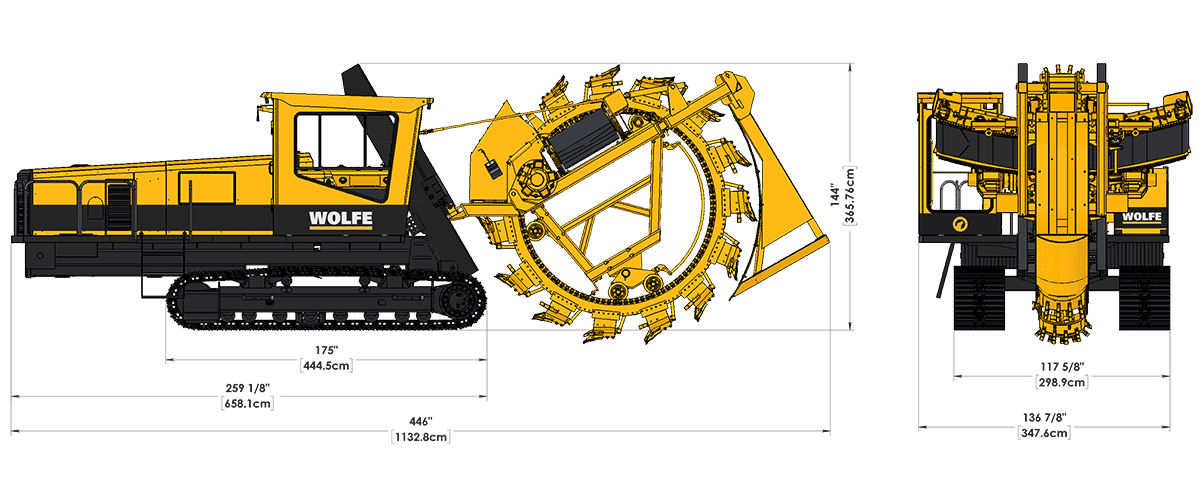

Technical Drawing

All machines are licensed by the Ontario Minsitry of Agriculture, Food & Rural Affairs (OMAFRA).