- Preventative maintenance help tool

- Preventative maintenance calendar

- Maintenance schedule

- Push notifications for maintenance group

- Diagnostics screens for system inputs and outputs

- Access to Web portal and link from customer to manufacturer to view machine real time

CT7040

Trencher

Trench with Power

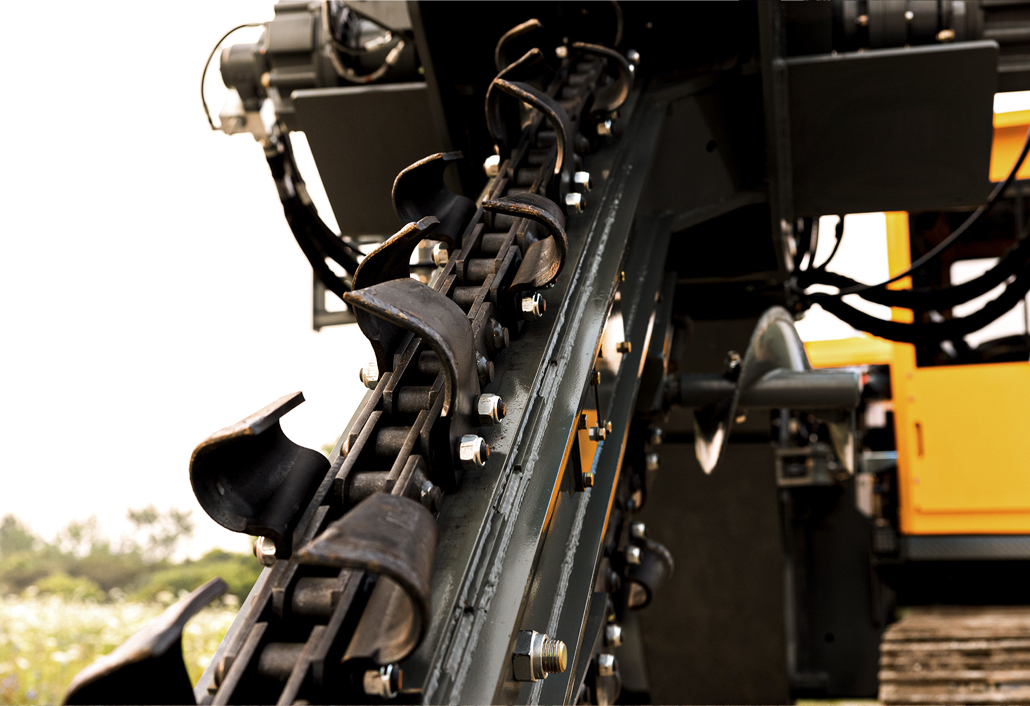

- The Wolfe Chain Trencher features a chain with a maximum cut width of 24” [61cm] & depth of 7ft [213 cm].

TRENCH WITH POWER

The Wolfe Chain Trencher features a chain with a maximum cut width of 24” [61cm] & depth of 7ft [213 cm].

Digging Boom

Digging Boom capable of 7ft depths.

7 DEGREE SIDE TILT

The side tilt feature automatically or manually keeps the boom vertical ensuring a precise grade on sloped terrain.

CENTRAL LUBE STATION

Allows safer and easier greasing from central locations. An auto-lube feature is available to reduce manual maintenance while ensuring that all lube points are getting the proper amount of grease.

ERGONOMIC MACHINE CONTROLS

Ease of use and operator comfort are always top of mind. Operators need to be comfortable and confident in the machines. Wolfe understands these challenges so we moved to ISO-style controllers – allowing operators to be already familiar with the controller layout.

UNDERHOOD ACCESSIBILITY

The hoods are designed with extra clearance when open for easy maintenance access to the engine and hydraulics.

REEL CARRIER

The compact design has the ability to be folded up for easy transportation and quick field-ready transitions.

Features

-

456HP CAT™ C9.3 ENGINE

-

Ergonomic Machine controls

Ease of use and operator comfort are always top of mind. Operators need to be comfortable and confident in the machines. Wolfe understands these challenges so we moved to ISO-style controllers – allowing operators to be already familiar with the controller layout.

-

Output/Productivity Control

An adaptive, on-the-go control system designed to enable automatic ground speed control during installation. This System relies on engine loads and system pressures to change the ground speed to compensate for variations in soil condition that the operator can not see.

-

Optimal Machine Cooling

The machine cooling system is designed with variable speed reversing fans. The variable speed fans help reduce fuel consumption while the auto / manual reversing feature makes for easy cleaning when operating in dusty conditions.

-

7° Side Tilt

The side tilt feature automatically or manually keeps the boom vertical ensuring a precise grade on sloped terrain.

-

Underhood Accessibility

The hoods are designed with extra clearance when open for easy maintenance access to the engine and hydraulics.

-

Central Lube Station

Allows safer and easier greasing from central locations. An auto-lube feature is available to reduce manual maintenance while ensuring that all lube points are getting the proper amount of grease.

-

Cable Guides and CONDUIT REEL CARRIER (Option)

Hydraulically controlled cable guides allow the cable/conduit to be loaded at ground level. No need to use auxiliary equipment to load. The remote control system also allows the operator on the ground to have full visibility of the loading procedure and insure the cables/conduit are not damaged as they are raised into position.

-

LAYBOX DESIGN & FABRICATION (Option)

As engineering and installation specifications can change from job site to job site custom laybox design is a value added item we can offer our customers.

-

REEL CARRIER (Option)

The compact design has the ability to be folded up for easy transportation and quick field-ready transitions.

-

Web APP & Remote Connectivity

This new addition to Wolfe’s diagnostic system allows for our technicians to connect remotely to your machine as well as assist you with job site requirements. It can prompt Safety and PM checks, Capture Stoppages, and push service notifications/service schedules.

Standard Equipment

- State-of-the-art Plus+1® Electronic Over Hydraulic Control System with complete machine monitoring, diagnostics and feedback to protect your machine for the long term

- Two-Speed Drive System with Output/Productivity Control

1st Max: 120 ft/min [2.19km/h]

2nd Max: 260 ft/min [4.75km/h]

C/W Programmable Dig Mode - Proportional Hydraulics

- CAT 320 Style 49 Link Tracks with standard pads

- Side mounted cabs to increase the visibility of the work zone and sight line while driving

- Ergonomic Machine Controls

- A/C and Heated cabs C/W digital climate control

- Air Ride Seat

- Digging Boom capable of 7ft depths & 24” wide

- Engine cooling system with auto/manual reversing fans for cleaning during operation in dusty conditions

- Under Hood Accessibility

- GPS, Auto/Steer and Laser Ready

- Built-in air compressor

- Machine Weight: Approx. 65,000lbs [29,484kg]

- Auto Idle

- Engine Block Heater

Optional Equipment Add-Ons

- Compact Reel Carrier

- Cable Guides & Conduit

- Reel Carrier (With remote actuation for ground crew control)

- Auto/Manual Lube Manifold

- Custom Colours Available

- Hydraulic Oil Pre-Heater

- Cable Tow System

- Cameras and View Monitors

- Lights

- Custom Laybox Designs

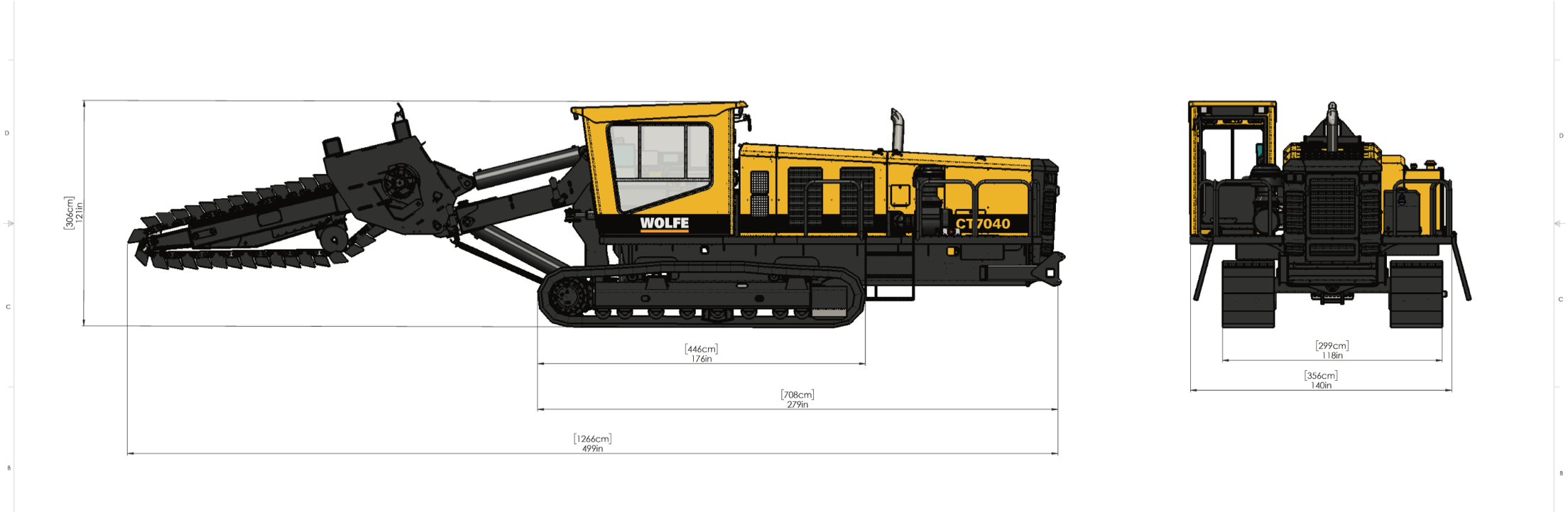

Technical Drawing

wolfe equipment app

FEATURES

All machines are licensed by the Ontario Minsitry of Agriculture, Food & Rural Affairs (OMAFRA).